Casting Process Simulation Leads to Considerable Cost Reductions

Karl Scherb foundry strengthens its market position with MAGMASOFT®

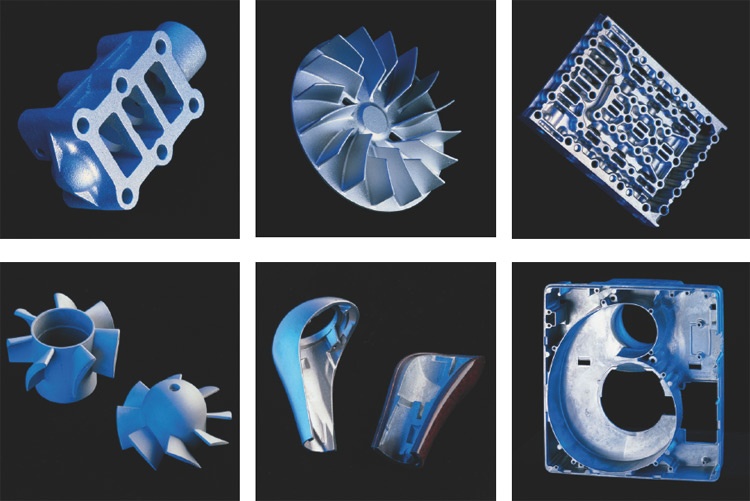

Karl Scherb is a conventional medium-sized foundry with 79 employees and an annual turnover of around 9 Million Euros (2009) located in the south of Germany. They produce aluminum components in die and sand casting processes for the automotive, heating, medicine, and mechanical engineering industries, mostly in small and medium-sized production runs. “Beside the manufacture of castings, we want to offer our customers additional expertise with respect to the development of cast components, tooling and casting processes. Secondly, we strive to produce cast components that accurately and documentably fulfill our customers’ requirements and specifications with maximum cost-effectiveness.” This is the way in which Managing Director Markus Scherb explains the strategy used by Metallgießerei Karl Scherb GmbH to set itself apart from competitors.

For Scherb, a crucial cornerstone to realizing this strategy is MAGMASOFT®. He has been employing the software, which he first came in contact with during his studies at RWTH Aachen University, for many years now. “With MAGMASOFT®, we started with a tool that had not yet been applied in many foundries and which now helps us in the analysis and the design of the complete ‘casting value chain’. This provides a valuable competitive edge in both the range of our offerings and the cost-effective production of high-quality castings”, Markus Scherb sums up the corporate benefits of MAGMASOFT®.

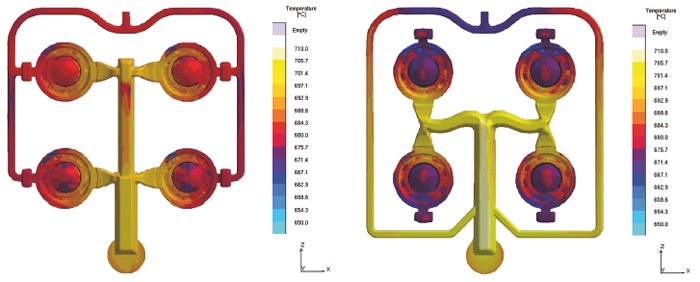

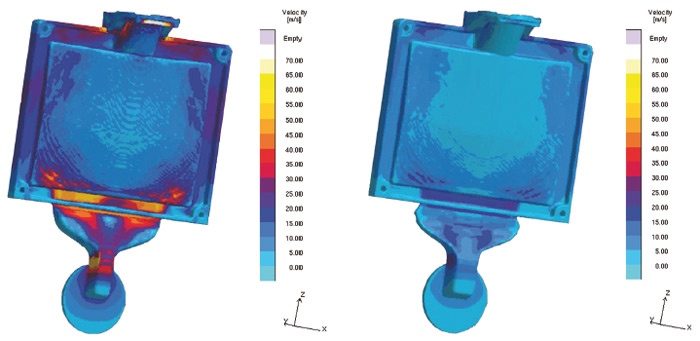

The connection between economical and technical benefits of casting process simulation with MAGMASOFT® can be clearly illustrated in a benefit pyramid: The constructive use of the software for the lay-out of tool-ing, gating and risering design and finally the control of the solidification process leads to optimum tooling and patterns. This, in turn, is the basis for high-quality cast components. The successive cost savings ultimately result in a higher profitability.

Scherb runs up to 300 simulations yearly leading to Euro savings running into five digits, as illustrated by the following selected examples:

Scherb saved roughly 12,000 Euros because they managed to correct the gating system of a tool during samp-ling before the start of production. Cost savings of 25,000 Euros were realized through the modification of a gating system, reducing metal velocities at the ingate in order to reduce mold wear and extend the tool’s lifetime. A cost reduction of 20,000 Euros was realized through reduced testing and inspection efforts, since the reconstruction of a die insert resulted in reduced pore formation. The reduction of cold flow problems by using a new ingate system saved another 11,000 Euros.

With roughly 100 different projects per year, it becomes obvious which crucial role casting process simulation has for the profitability of the foundry – without taking into account the increased revenue that Scherb realizes through new customers convinced by the argument “casting process simulation”.

„MAGMASOFT is a strategic investment for us because the software decisively improves our market position and economic situation”, sums up Markus Scherb with a view to the challenges outlined above. “With this we were able to establish ourselves as a partner for industries with sensitive and demanding cast components like gear boxes, thread guides for textile machines, components for pre-combustion chambers for heaters, and surgical microscopes”.

“Moreover, the software protects us from losing know-how, as now the knowledge is stored not only in an expert’s brain but is also saved so that it can always be re-used in the databases of MAGMASOFT”, confirms Markus Scherb.