HIGHLIGHTS & BENEFITS OF MAGMA - Permanent Mold

Highlights IN MAGMASOFT® 6.0

New capabilities and new algorithms provide a better and more accurate representation of the complete permanent mold casting process for:

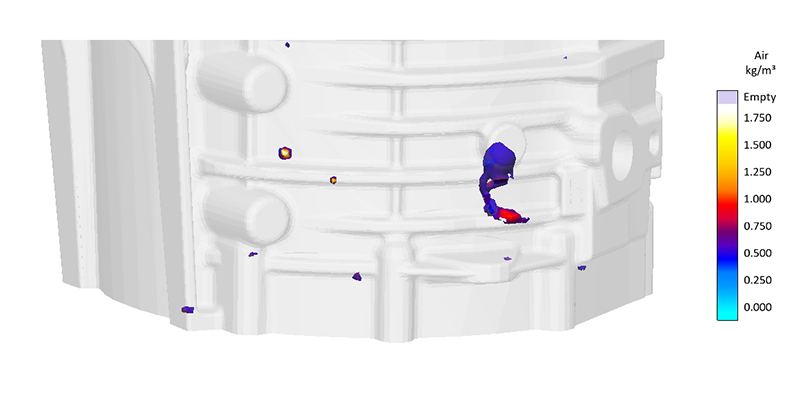

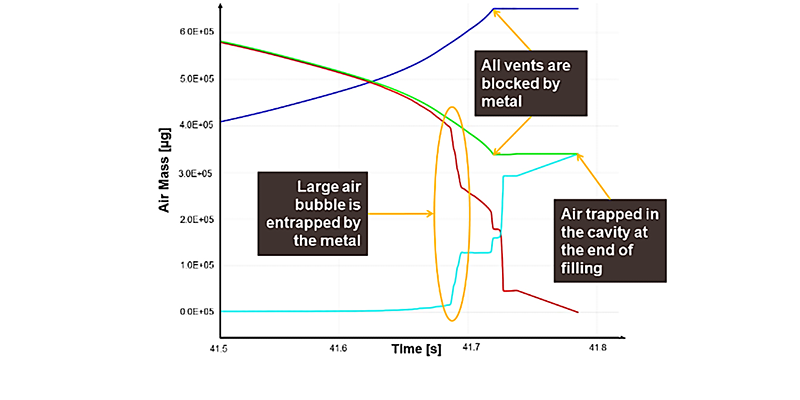

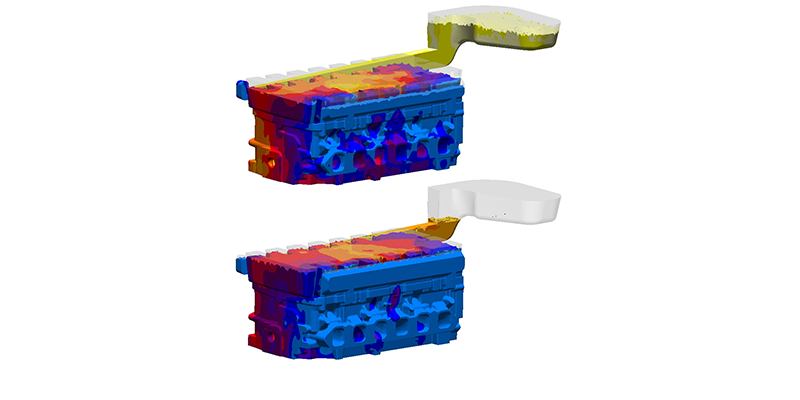

- Following and evaluating entrapped air in the gating and casting during pouring

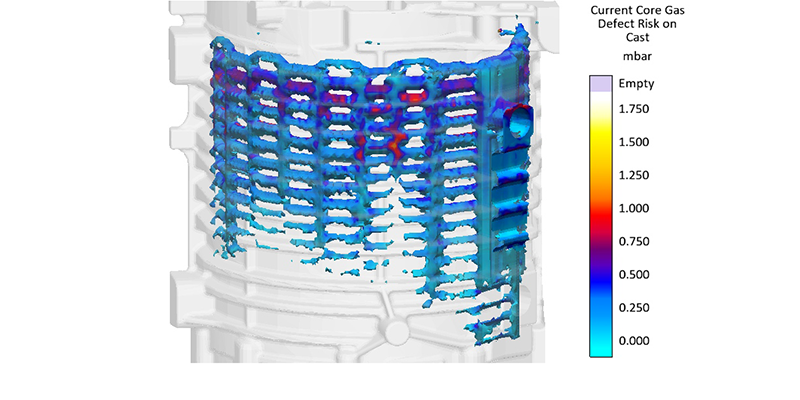

- Generation and transport of core gases during filling and solidification

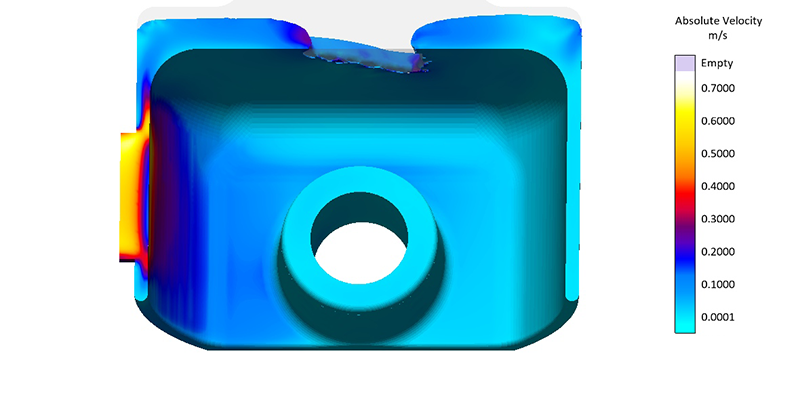

- Effects of melt surface tension and wetting

- Accurate description of the pouring conditions for the casting

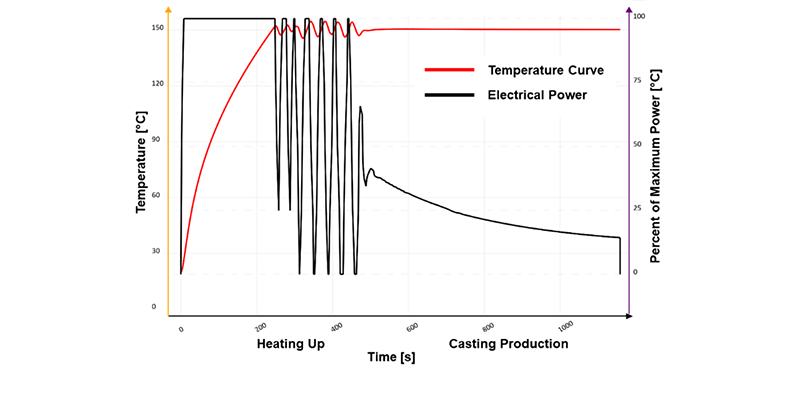

- Heating of the mold before starting production

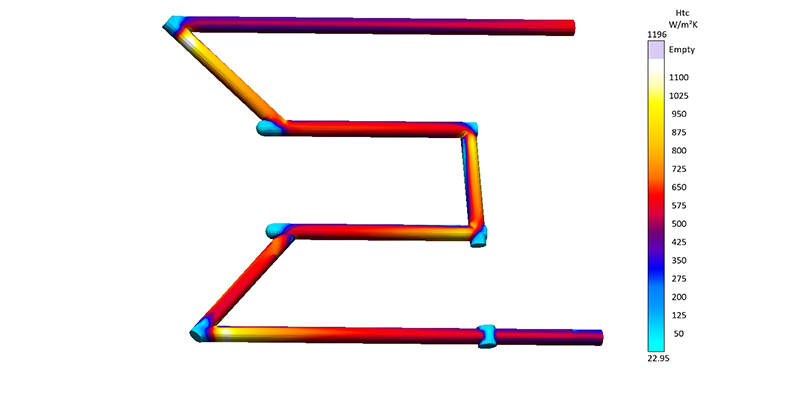

- Influence of flow through cooling lines on local heat transfer from the die

- Effects of electrical heating cartridges and Variotherm control on the die thermal balance

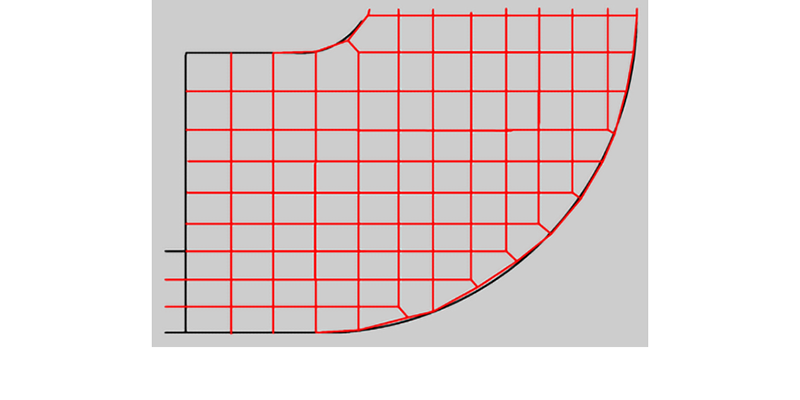

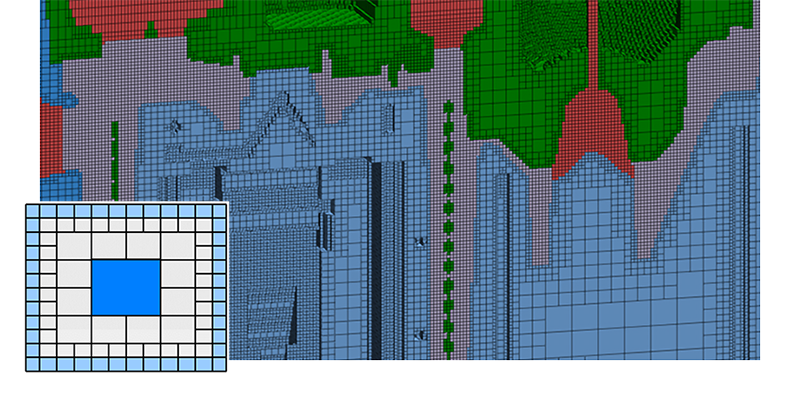

- TAG meshes for an accurate representation of the casting contour and fewer elements with mesh coarsening

YOUR BENEFITS

The right tools for decision making in casting and tooling design, optimizing casting layouts and production processes:

- Faster and more robust decisions due to an easier assessment of entrapped air in the casting

- Shorter development times through an improved understanding of entrapped air and core gases on casting quality

- Time savings in tooling layout by a better understanding of the heat balance in the die

- Higher productivity due to optimal preheating of the mold before producing the first casting

- More quickly achieve optimized casting layouts and processes through shorter calculation times

Última Publicação

MAGMASOFT® 6.0 – Tornando a simulação simples e fácil

MAGMASOFT® 6.0, a nova versão do conhecido software de simulação de processos de fundição, oferece agora uma experiência de uso fundamentalmente nova. Os usuários alcançam seus objetivos ainda mais rápido, graças ao foco especial colocado na facilidade de uso e no tempo de resposta.

Requisitos do sistema

MAGMASOFT® está disponível para todos os sistemas operacionais atuais, tais como Linux e Windows 10. O MAGMASOFT® pode ser usado em computadores due core ou multiprocessados ou computadores no sistema cluster.