Innovative Product Design and Robust Process Layout in Die Casting with Autonomous Engineering

Horst Bramann, Laura Leineweber und Jörg C. Sturm, Aachen

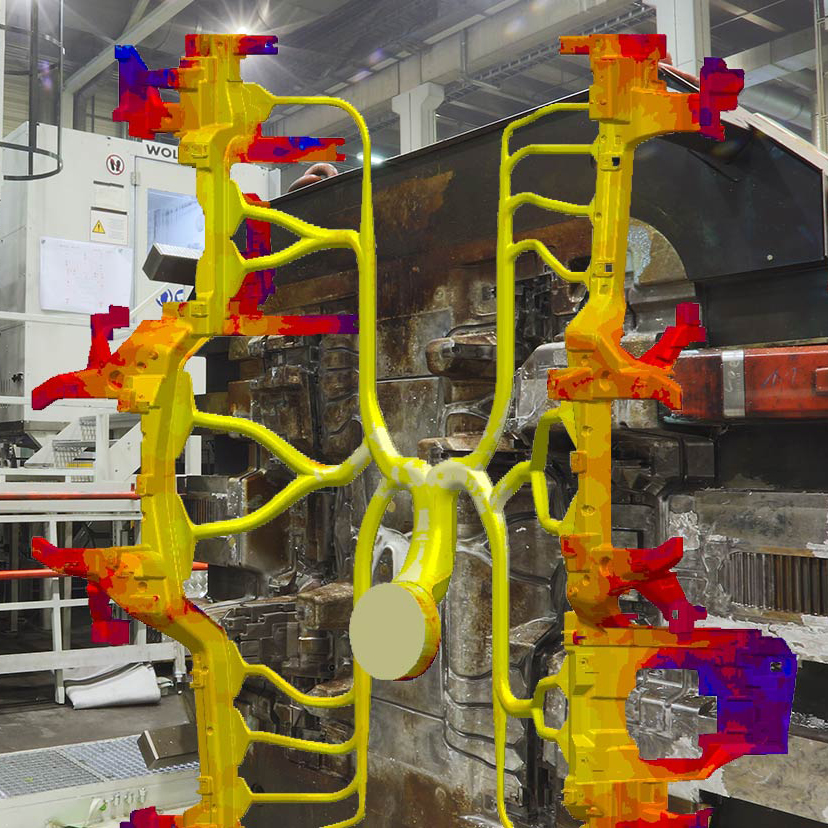

Innovative automotive lightweight designs lead to a higher demand for the product and process development of die cast components. This is attributed to shorter and shorter product development cycles as well as the rising functional integration and complexity of structural die cast parts. The main objectives of the technically complex processes and tools in aluminum and magnesium die casting are cost and resource efficiency along with the robust fulfillment of the defined high-class requirements of the casting. In this context, casting process simulation is a well-established tool used to support tool design, part design as well as process development.

Using the example of a structural die cast part this paper demonstrates how the new methodology of Autonomous Engineering of MAGMASOFT® 5.4 contributes to the demands of die casting for:

- faster product and process development,

- optimum process and tool design in terms of quality, yield and costs, as well as

- robust process layout with maximum reproducibility of quality

better than ever before.

[...]

The complete publication is available in the linked PDF.

Innovative Product Design and Robust Process Layout in Die Casting with Autonomous Engineering