Significant Reduction in Time and Effort for Rework

The foundry Roucka Slévárna, a.s. manufactures castings for the industrial sector, primarily focusing on fittings and pumps. Erich Roucka founded the company in Brno, the second largest city of the Czech Republic, as a boiler producing factory in 1929. The production portfolio of Roucka Slévárna includes over 50 types of steel – carbon, low-alloy, high-alloy, and stainless steel. In addition, they cast special nickel-based alloys such as Monel, Incolloy, Duplex, and Hastelloy. New investments allow the production of castings ranging from 1 to 10,000 kg and a new factory offers the possibility to produce ductile iron castings.

Due to the increasing technological requirements during casting, as well as the need to cut production costs, Roucka Slévárna decided for the use of MAGMASOFT®. Numerous calculations have been done using the software since the system was put into operation. Currently, all relevant engineers are being familiarized with MAGMASOFT® and beginning to see casting process simulation as an everyday tool in finding optimal casting layouts.

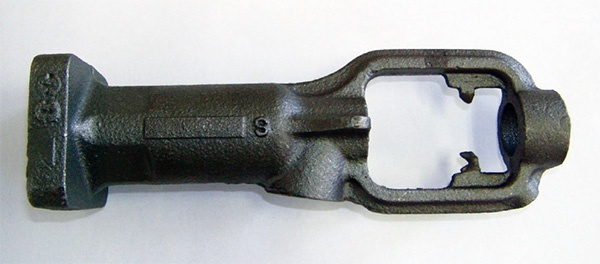

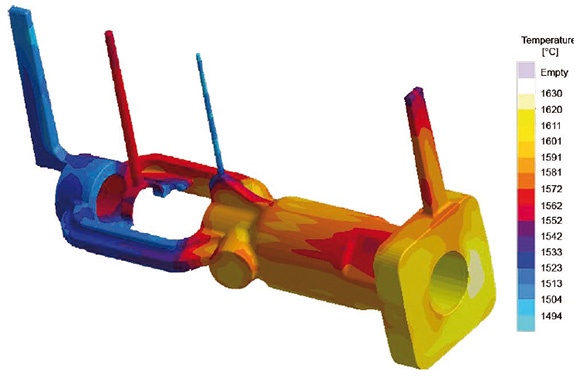

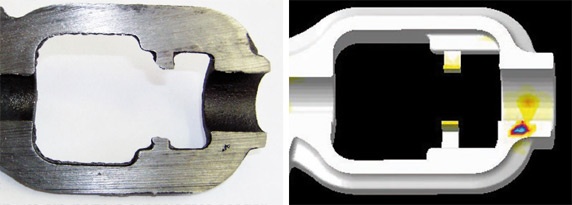

The following project shows a yoke cast in carbon steel. The material is cast at a temperature of 1630°C into a croning sand mold with a shell sand core. Here the simulation results have been verified on inspection of the parts and by X-ray. The pattern was revised using MAGMASOFT® and the shrink could be removed entirely.

After the pattern was optimized using casting process simulation, series production of the yoke has been launched amounting to approximately 1,000 components per month. Since Roucka Slévárna has expanded their production capacity for heavy castings using DISAMATIC® molding machines and through the simultaneous introduction of MAGMASOFT®, the company has achieved an important competitive edge. Especially in situations where heavy castings are to be produced using DISAMATIC® molding machines, a well-tuned pattern layout is essential for a reliable and economic production. Simulation before production allows the minimization and avoidance of casting defects. In addition to reduced costs through effective resource utilization and a reduced scrap rate, Roucka Slévárna could significantly reduce time and effort for rework.